HRDGCOIN

HRDGCOIN

HRDGCOIN protects the rights of digital assets and mediates secure transactions.

It is a trusted asset in the digital world that connects the real and virtual worlds.

-

DAI (Decentralized AI)

HRDGCOIN is a decentralized blockchain operated through AI and provides an optimized solution by analyzing the behavior patterns of participants taking part in the token economy.

-

Transaction

The AI-based sidechain works with the performance and consensus of the main chain to enable optimized transaction management for each service.

-

Stability

Through HRDGCOIN's DAI, it is possible to maintain a stable network by monitoring the network at all times and managing the efficient sidechain to flexibly process the transactions concentrated in a specific section

Saemyeong Energy Tech Group

Saemyeong Energy Tech Group is

a company specializing in research and development of eco-friendly products, and aims to supply raw materials such as high-performance combustion catalysts, lubricants, organic natural fertilizers, soil conditioners, feed additives, and bioceramics to the world. After China and Vietnam, we started to expand to Southeast Asia and Europe.

Saemyeong Energy Tech Group is adhering to the new strategic direction of block chain and eco-friendly energy in its overseas development strategy, so we propose an HRDG tree-type block chain that transparently distributes the entire distribution process of eco-friendly products to all subsidiaries through block chain technology.

By uploading it to the block, we will maximize the company's profits and at the same time provide various investment opportunities to ecosystem investors. As a resut, we will grow into a global symbolic eco-friendly energy company.

HRDG Ecosystem

-

P2P eco-friendly energy transaction

It is to enable energy consumers to actively participate in energy transactions and become energy prosumers. The prosumer referred to here not only general household energy consumers, but also commercial and industrial energy consumers can play the role of prosumers including trading physical and information in an end-to-end manner.

-

Mass transaction of eco-friendly energy

Energy trading is completed through common market mechanisms such as oil trading within blocks after packing information into blocks. It can automatically execute terms and conditions based on pre-set multi-conditions. It also automates procedures such as electronic documents, smart contracts and authentication transfers. So it is possibler to reduce transaction costs and risks significantly

-

Eco-friendly energy smart service

By utilizing the characteristics of transparent & safe blockchain and the advantages of smart contracts, eco-friendly energy companies can increase the level of smartization of their current work and provide more various smart value-added services. In addition, by applying smart contracts to wholesale transactions of eco-friendly energy, transaction risks and management costs can be reduced.

-

Tracking of eco-friendly energy assets

Supply chain management and tracking function of blockchain technology enable the most basic functions such as anti-counterfeiting inquiry and consumer feedback, not only product information such as brand, country of origin, selling point but also company-related information such as company level and safety certification. It also enables information retrieval on import certificates, import cargo quarantine certificates, customs declarations, etc.

-

Supply chain finance

Supply chain finance is a system in which all participants (suppliers, importers, banks) share documents through a decentralized ledger and pay automatically when a scheduled time or result is reached. This increases efficiency and at the same time prevents errors caused by manual transactions, and creates a smooth information flow throughout the entire supply chain, maximizing the efficiency of supply chain management.

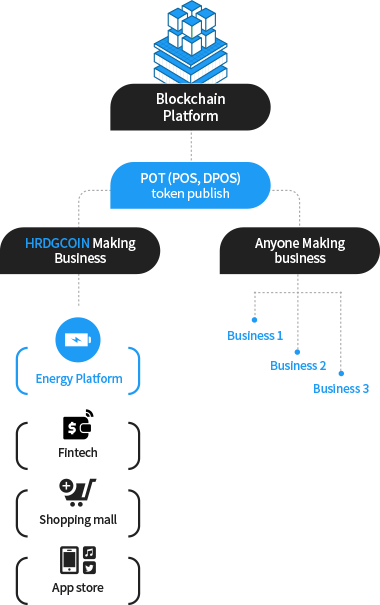

Introduction to Blockchain

The HRDGCOIN Team develops the HRDGCOIN ecosystem and issues HRDGCOIN by gathering eco-friendly energy developers and blockchain experts to solve various problems in the eco-friendly energy market and the global overseas remittance market. HRDGCOIN is used as a key currency within the eco-friendly energy and global fintech ecosystem.

-

- HRDGCOIN economy without borders

- Without borders, all members of the economy, energy, fintech and countries around the world will be united with the word HRDGCOIN Network. And they will become a member of the HRDGCOIN ecosystem.

-

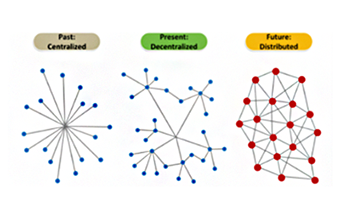

- Public security through Public & Personal decentralization

- It refers to the structure of an ecosystem through realization of public security through decentralized information management, which is the security core of blockchain technology and coexistence between individuals and the public.

-

- Highest speed and real-time processing for energy and fintech commercialization

- The HRDGCOIN platform, a third-generation blockchain, will become a world standard energy and fintech PUI blockchain based on real-time reflection and fast block processing, which is very important for energy and fintech.

HRDGCOIN Platform

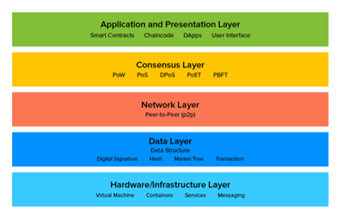

HRDGCOIN Technical Frame

HRDG provides a complete development model and technology frame

for the entire blockchain technology ecosystem.

The combination of blockchain technology and eco-friendly energy industry using a design method verified through long-term experiments is a epochal leap forward.

More importantly, HRDG has laid an excellent foundation that will go down in history in the ecosystem through the combination of blockchain technology and the eco-friendly energy industry.

-

Network layer

Network layer

After generating block data by executing the core node program on the network node of HRDG, it performs functions such as simultaneous data update between each node.

-

Tree structure

Tree structure

It stores system block data through a tree-type block structure based on 'Security Main Chain + Multiple Application Sub-chains'

-

Cross-chain template

Cross-chain template

HRDG cross-chain templates and e-commerce templates do not require a VM compiler and have excellent operational efficiency.

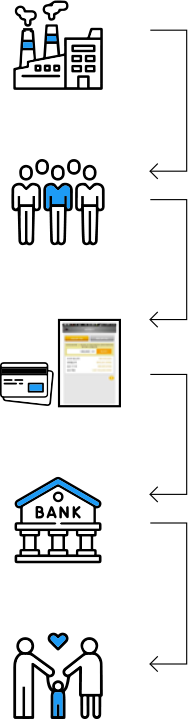

VERON Pay App_Overseas remittance

- Currently, there are about 150,000 Vietnamese workers living in Korea, and about 70-80,000 workers are replaced every year due to the expiration of work visas every three years.

- Remittance fees are high and the remittance speed is slow when remittance from a bank in Korea to Vietnam.

- Exposure to risks such as currency exchange, tax evasion and money laundering when using a private currency exchange

Small and medium-sized enterprises of Korea

Vietnamese worker

VERON Pay App

A bank in Vietnam

Family in Vietnam

Salary remittance

Salary transfer

Remittance to Vietnam

Withdrawal

Small and medium-sized enterprises of Korea

Vietnamese worker

VERON Pay App

A bank in Vietnam

Family in Vietnam

Salary remittance

Salary transfer

Remittance to Vietnam

Withdrawal

- 24-hour online service access

- Lower remittance fees and faster transfer time compared to bank remittance

- Convenient services such as Vietnamese language support

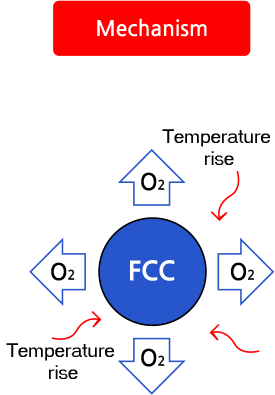

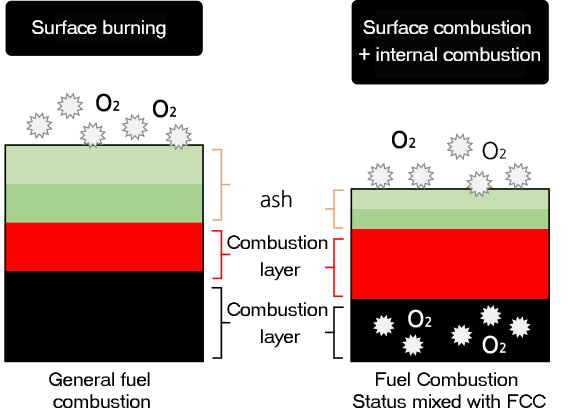

FCC (Fuel Combustion Catalyzer)

In general, incomplete combustio occurs because the oxygen supply inside the fuel is not smooth.

- → Fuel + FCC mixture → Combustion temperature rises to a constant temperature → Oxygen is generated from FCC

- → FCC supplies oxygen to fuel that lacks oxygen → promotes complete combustion of fuel

- → Fuel savings + reduced air pollutant emissions

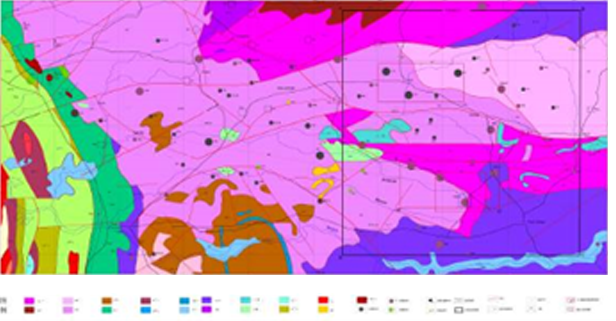

Manganese Mine

Located in Maranje Province in the northwestern Republic of Angola, the mine is 15km wide to the south and is 268m high with a minimum of 840m above sea level and a maximum of 1108m above sea level. The direction of the main ridge is northwest-southeast, and gradually changes to the north-south direction to the east, with gentle hills in the middle and high mountains in the north. The total mining area is 576㎢

Metamorphic rocks of the old ancient system, an old basal primordial system, and the sporadically distributed Mesozoic Cenozoic strata. The strata are the old basal and cover layers, respectively, from old to new layers.

Archaeological subgroup (Ag1)1) Contains manganese granitic gneiss, ileal gneiss, metamorphic rock and forms iron manganese deposits related to sedimentary alteration. It is the main layer of the manganese oxide mine in Angola.

Ancient Sangam Cluster (Ag1)2) It is composed of Baegun 2 gneiss, granite gneiss, schist, amphibole and magnetite quartzite. As a result, the growth of quartz rock, which is a lithotropic magnet, became common. And iron ore deposits related to the drying of silicate were frequently formed, reflecting the main stratum of Angola's iron ore and manganese carbonate ore.

Old ancient lower rock cluster(Pt1)1) gneiss, layered andesan basalt.

The old ancient Sangam Cluster (PT1)2) Rock formations are mainly composed of clasts and carbonate rocks, and are major deposits of nonferrous metals such as Angola copper, sedimentary iron and manganese deposits. This rock was found to form mixed granite due to the occurrence of mixed rocks in different amounts within the premises.

In the stratification, the main system (K) - the tertiary system (N) - the quaternary system (Q) are mainly distributed sporadically. Among them, the Cretaceous period and the Tertiary period are carbonate rocks and clasts, and the carbonate rocks are Angola cement which is the main producer of gray rock.

Accumulated post-pay travel

Accumulated post-pay travel

Accumulated post-pay travel

is a new method of paying

the supported amount of

money for a certain period

of time after a trip with

200% of a member's

accmulated amount

If a member start to

accumulate a certain

fee every month after

signing up, the member can

apply for trip after 6 months!

- Planned trip A meber can enjoy the trip as planned by selecting the products of the allied travel agencies including our own travel products.

- A trip without a lump sum of money A member can travel with support of up to 200% of the member's accumulated amount.

- 100% responsibility system 100% refundwill be given in case of non-performance as quoted (airline, accommodation, meals).

- Possible to transfer Possible to transfer from/to another person

- ESCROW 50% of membership payment is deposited in banks(SACOM, POST, VP) and stored safely.

TOKEN Distribution

Total Supply

2,000,000,000 HRDG

- Private Sale

- Pre Sale

- R&D and Future Business

- Company

- Team

- Advisors

- Bounty

History & Road map

- 2018. 11

- Establishment of Semyung Energy Tech Group

- 2019. 03

- Establishment of Remex Lubricating Oil Plant, a joint venture in China

- 2020. 08

- Implementation of business model and logic, establishment of HRD model and burning plan

- 2020. 09

- Establishment of Dowoon Energy Tech Group

- 2020. 09

- Project drafting and official launch, team formation completed

Establishment of HRD China Regional Office

- 2020. 11

- Conducting market sale in Vietnam market with Changchun Limais Lubricating Oil Manufacturing Co., Ltd.

Preparatory work started for user recruitment and community expansion in the Chinese market

- 2020. 12

- Network synergy creation for building nodes in each region of China

- 2020. 12

- Listing on Global Exchanges WBF, DCOIN, PROBIT

- 2021. 03

- Establishment and operation of an eco-friendly lubricant manufacturing plant

- 2021. 05

- VERON Pay platform planning

Branches' installation completion of 500 oil injectors for Vietnam's motorcycles

Completion of 2000 branches' contracts

- 2021. 06

- Business alliance with Nam A Bank in Vietnam

- 2021. 10

- Launch of VERON Pay platform, a global fintech

- 2021. 12

- Launch of the global energy HRDG Energy platform

Listing on major Global Exchanges

- 2022. 06

- Partnership with 2,000 eco-friendly energy partners

Team

-

HuiSu Park

HuiSu ParkCEO

-

PanYong Jang

PanYong JangCFO

-

Meitao

MeitaoCTO

-

Sa Lim

Sa LimDeveloper

-

HyoSeung Moon

HyoSeung MoonDeveloper

-

DongHo Seo

DongHo SeoDeveloper

-

KyeBong Choi

KyeBong ChoiDeveloper

-

Sermpon Tilakul

Sermpon TilakulMarketing

-

Samuel Pham

Samuel PhamMarketing

-

Tran Thi My Linh

Tran Thi My LinhMarketing

Advisor

-

NamJung Hong

NamJung HongChairman of Veron Esset

-

JaeKwan Moon

JaeKwan MoonCEO of Veron Esset

-

Aaron Jin

Aaron JinCEO of EveryCoin

-

JINMEITING

JINMEITINGAdvisor

-

DongWook Jung

DongWook JungUbiquitous leadership

-

JongGeun Oh

JongGeun OhPresident of International Trade Association

-

YeonSu Kim

YeonSu KimCEO of Dudumax

-

MyungChul Shin

MyungChul ShinSaemyung Energy Tech Planning Team Leader

-

MyungSun Lee

MyungSun LeeHead of HanVe Language Institute

-

KyuJin Cho

KyuJin ChoChairman of Hanul Agriculture Industry

-

JongGil Park

JongGil ParkPresident of the Australian Core Group

-

JeongCheol Jeong

JeongCheol JeongAdvisor

-

MunHwa Bae

MunHwa BaeAdvisor

-

朴玉花

朴玉花Advisor